Automatic Pre-cooling System Overview for myself

6/21/2006 Tokoku

- Objective

(1)Save troubles and man-power.

(2)The system is necessary for MOIRCS, COMICS, and CIAO.

The pre-cooling pipe of COMICS and CIAO (the same system) are

made of stainless steel with welding(=tough) and that of MOIRCS

is made of copper with silver soldering(=fragile).

COMICS and CIAO don't mind a flow rate.

COMICS takes 2 daytime operations, CIAO takes 1 daytime operation for

pre-cooling. MOIRCS takes 7 daytime operations with serious care.

(3)It is not clear whether this sytem will be allowed to run during night

time on safty grounds.

- Current Status

(1)Mechanical : Almost done. We want to add a vacuum system for LN2 pipe

for in case of high pressure inside.

(2)Software : Omata-san is improving it.

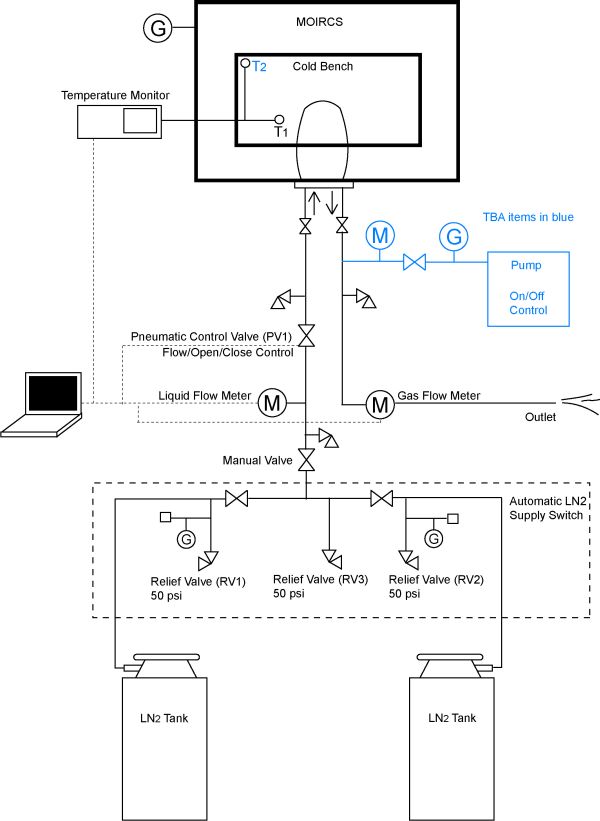

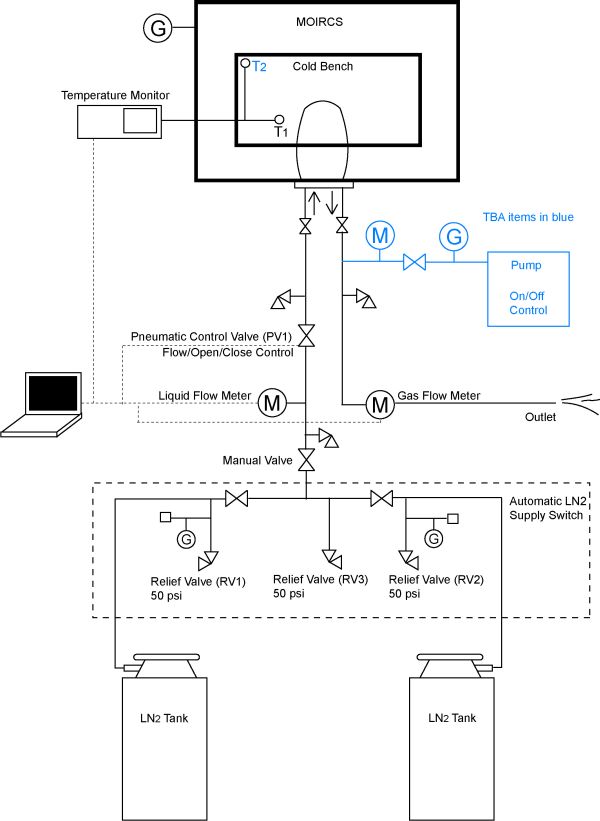

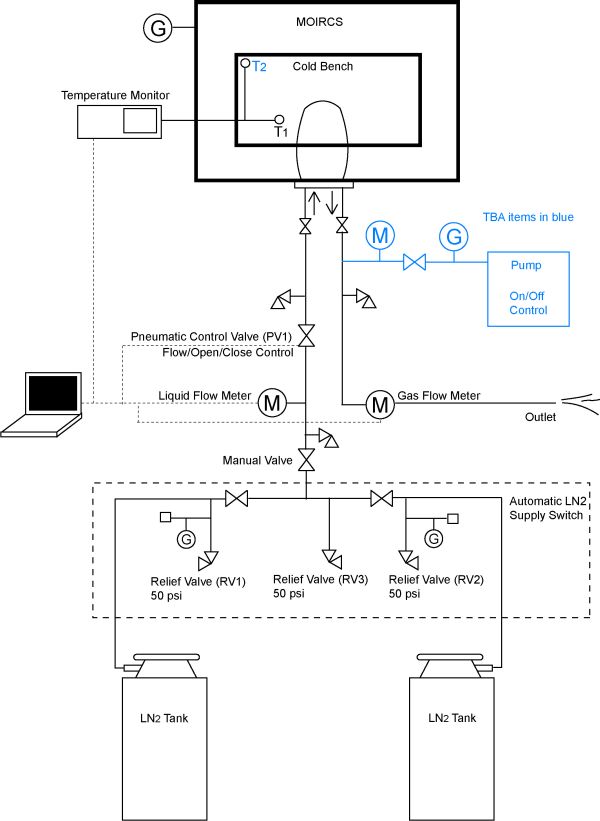

- Current Control System

Liquid flow rate control with adjustment OPEN/CLOSE of the pnumatic valve.

Set point(flow rate) are determined by liquid flow rate and temprature.

- Current Problems

(1)No secure measure for power failure.

(2)Need backup flow meter? (to where?)

- When is a vacuum system necessary?

(1)Avoid any damage from power failure.

(2)After PV1 was closed, if a puressure of G1 is too high (>10^-1 Torr??)

and

(3)During night time or When both tanks run out.

(4)How about using only relief valve?

---> Frost inside line.

---> Vacuuming during warm-up.

- Issues about a vacuum system in a liquid nitrogen line.

(1)The same line is used for liquid and high-vacuum.

(1-1)Connectors are difference.

(1-2)Gauges are difference.

(2)

(3)