| Aluminum Type |

Current |

Frequency |

Marking Speed |

Cutting

Feed Rate |

Result |

Comment |

Hard-temper

(alloy-1100/1145)

( t=0.003mm ) |

16 A |

1 kHz |

1 mm/s |

10 mm/m |

1 |

success=0/5 |

| 18 A |

2-3 |

success=0/5 |

| 19 A |

2-3 |

Current Method |

| 20 A |

2-3 |

success=0/5 |

| 21 A |

3-4 |

success=0/5 |

| 22 A |

3-4 |

success=0/5 |

| 23 A |

3-4 |

success=0/5 |

| 24 A |

3-4 |

success=0/5 |

| 25 A |

3 |

success=0/5 |

| 26 A |

2-3 |

success=0/5 |

| 27 A |

2 |

success=0/5 |

|

| 19 A |

1 kHz |

1 mm/s |

6 mm/m |

3-4 |

success=0/5 |

|

| 22 A |

1 kHz |

1 mm/s |

5 mm/m |

3-5 |

success=2/5 |

| 5 mm/m |

3-5 |

success=3/5 |

| 6 mm/m |

3-5 |

success=3/5, 15 min for 5 slits |

| 7 mm/m |

3-5 |

success=1/5 |

| 3 mm/s |

6 mm/m |

4-5 |

success=3/5 |

| 5 mm/s |

3-4 |

success=0/6 |

| 10 mm/s |

4-5 |

success=3/6 |

| 20 mm/s |

4-5 |

success=2/6 |

| 40 mm/s |

4-5 |

success=2/6 |

| 100 mm/s |

4-5 |

success=3/6 |

| 10 kHz |

1 mm/s |

6 mm/m |

1 |

success=0/5 |

| 40 kHz |

1 |

success=0/5 |

|

| 24 A |

1 kHz |

1 mm/s |

6 mm/m |

4-5 |

success=1/5, but others are very easy to be dropped |

| 8 mm/s |

3-5 |

success=0/5 |

Black anodized

( t=0.003mm ) |

19 A |

1 kHz |

1 mm/s |

5 mm/m |

4 |

FLAMINGOS's mask |

| 22 A |

5 mm/m |

4 |

success=1/5 |

| 24 A |

5 mm/m |

5 |

success=5/5 !! |

| 7 mm/m |

5 |

success=5/5 !! |

| 10 mm/m |

4 |

success=3/5 |

| 26 A |

10 mm/m |

2-3 |

success=0/4 |

Black painted

on usual mask

(alloy-1100/1145)

( t=0.003mm )

* |

22 A |

1 kHz |

1 mm/s |

6 mm/m |

3-4 |

Black magic marker

success=1/5 |

Black coated

(alloy-1100/temp-O)

( t=0.002mm ) |

19 A |

1 kHz |

1 mm/s |

5 mm/m |

4 |

success=1/5 |

| 10 mm/m |

4 |

success=3/5 |

| 22 A |

5 mm/m |

|

success=5/5 |

| 10 mm/m |

5 |

success=5/5 !!

4/8 outer slit cannot be cut |

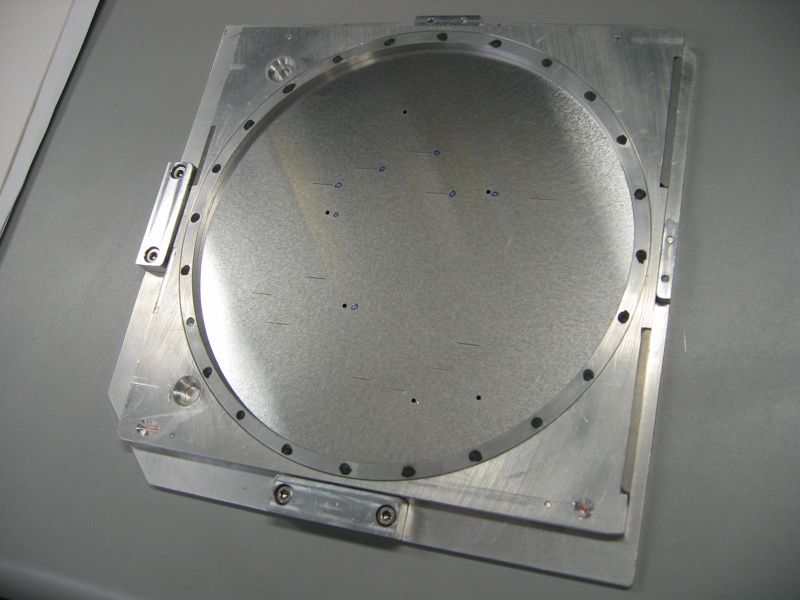

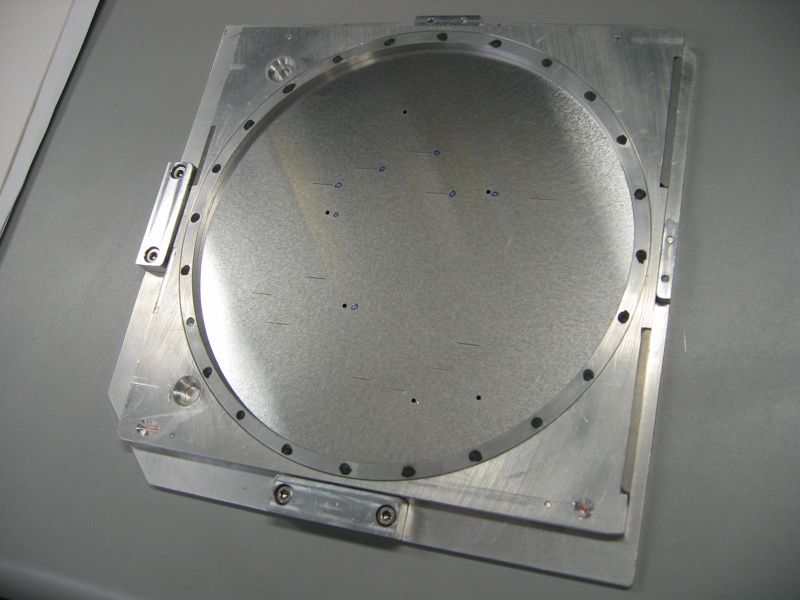

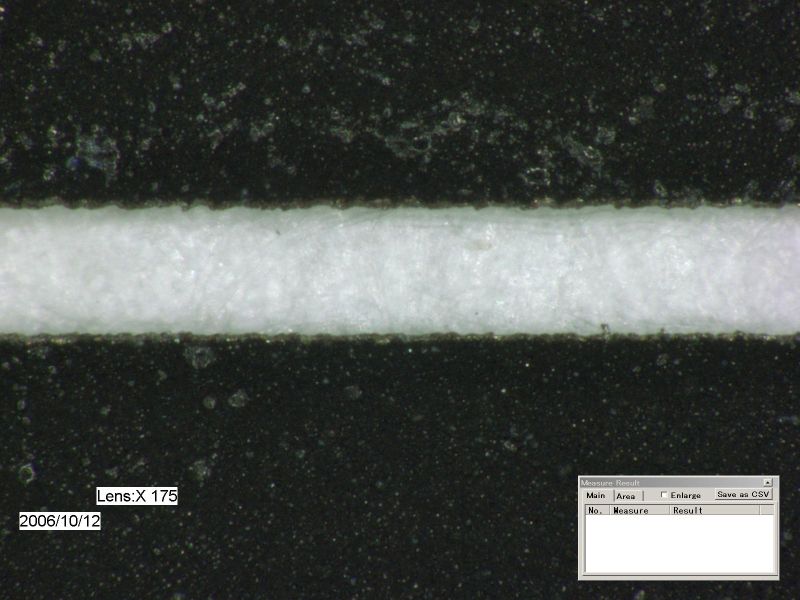

Black coated mask (top, back)

Black coated mask (top, back)

------------------------------

Update memo

------------------------------

10/10/2006

I tried to cut "black coated aluminum (t=0.002")" to make sure if the problem

is reflection of laser beam (power loss).

10/6/2006

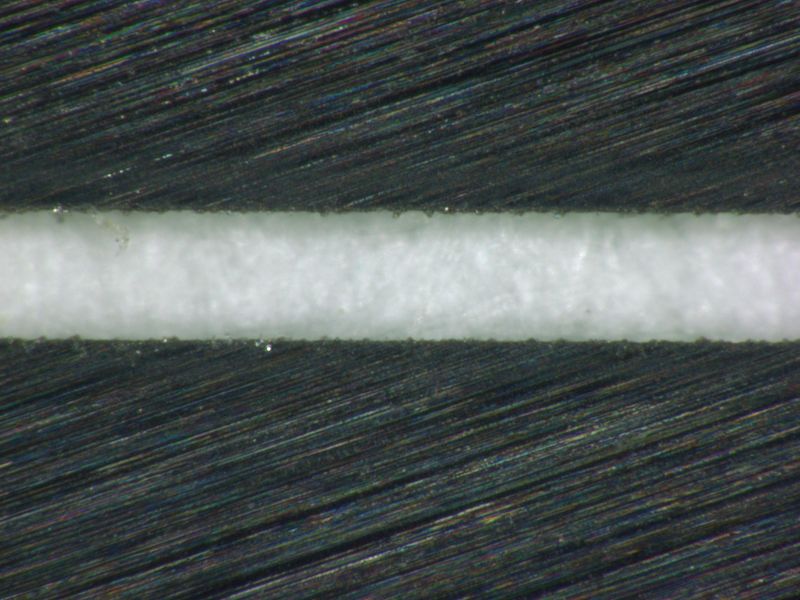

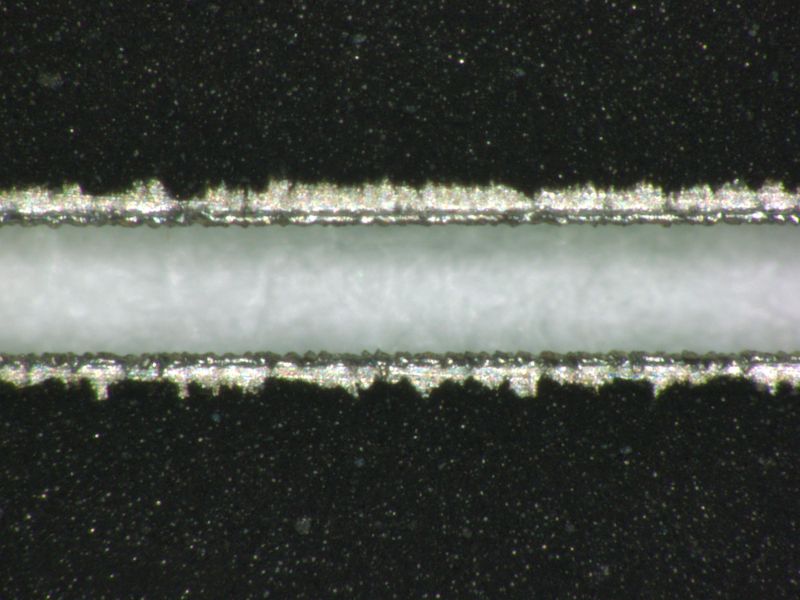

I could completely cut the black anodized mask for 1-time cutting(24A, feed=5-7mm/m).

10/5/2006

I cut a whole mask as the same science mask with best-cut settings(22A, feed=6mm/m).

There seems to be many dull slits at outside of a mask.

The same can be said always for other settings.

10/4/2006

I moved a left-lower hardstop for the laser and adjusted its position.

Now both FOCAS's and MOIRCS's frames can be fit snugly.

10/3/2006

Somehow the laser work bench alignment is wrong.

MOIRCS's cutting frame cannot fit the bench now.

At the moment, I test parameters with FOCAS's frame.

------------------------------

Update memo

------------------------------

10/10/2006

I tried to cut "black coated aluminum (t=0.002")" to make sure if the problem

is reflection of laser beam (power loss).

10/6/2006

I could completely cut the black anodized mask for 1-time cutting(24A, feed=5-7mm/m).

10/5/2006

I cut a whole mask as the same science mask with best-cut settings(22A, feed=6mm/m).

There seems to be many dull slits at outside of a mask.

The same can be said always for other settings.

10/4/2006

I moved a left-lower hardstop for the laser and adjusted its position.

Now both FOCAS's and MOIRCS's frames can be fit snugly.

10/3/2006

Somehow the laser work bench alignment is wrong.

MOIRCS's cutting frame cannot fit the bench now.

At the moment, I test parameters with FOCAS's frame.